Digital elements for the studio.

As an ever present studio element, digital resources are helping us shape the contemporary ceramics studio experience. We are going beyond the direct production of objects as digitally produced elements of focus, and viewing the printed as a direct link to tool production. Rethinking the digital element as a tools source and studio aide opens the door to endless possibilities on how makers with traditional approaches can use the digital elements as aide rather than a replacement. Included on this page are files for you digital printer to produce studio tools that have direct applications to hands on production. Please feel free to use tour files and make them your own and please share your designs with us. All shared files will be cited and attributed to the designer.

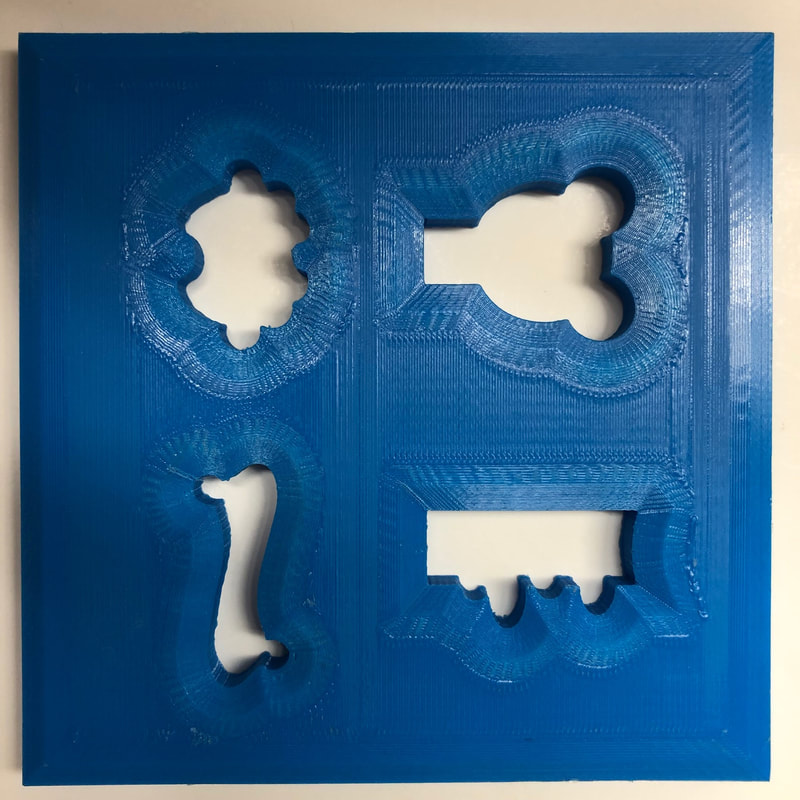

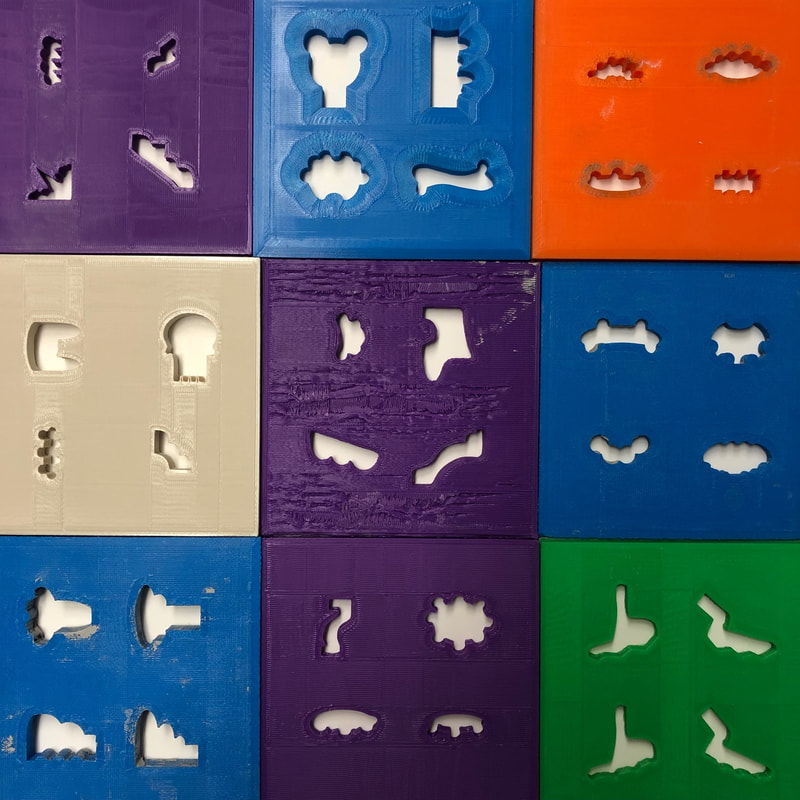

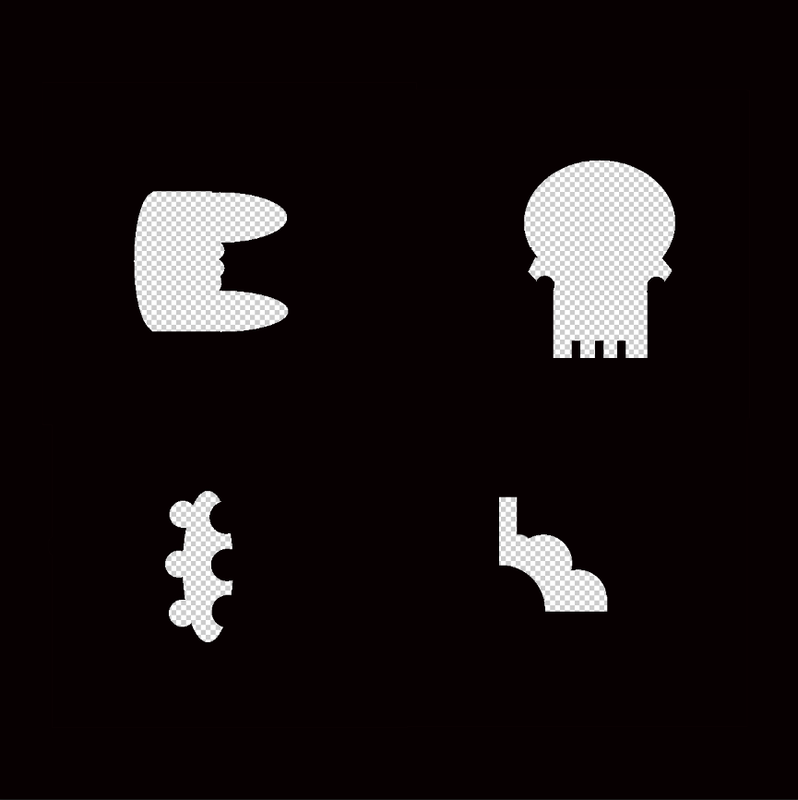

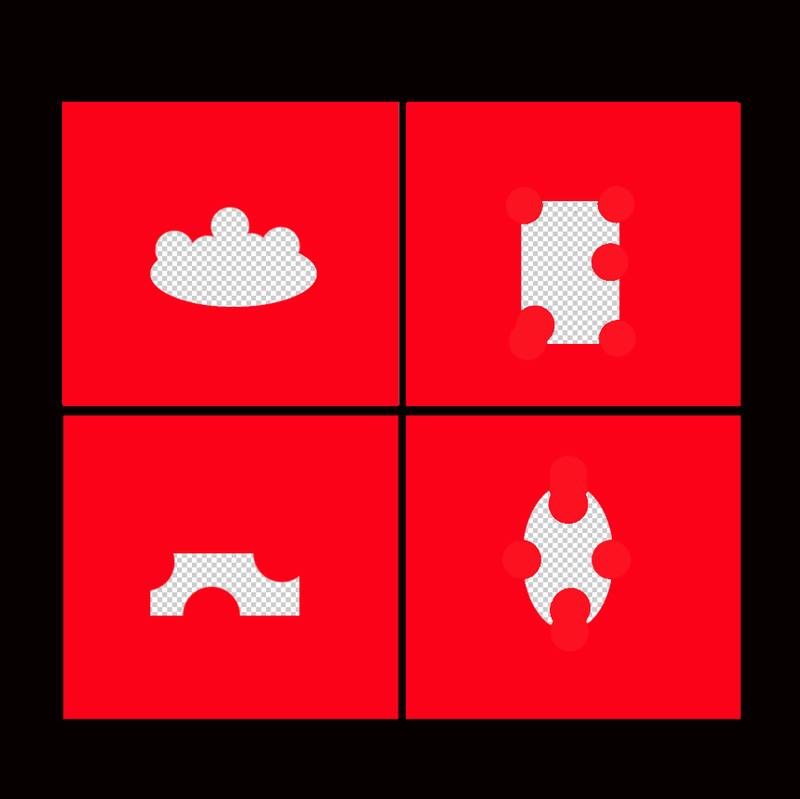

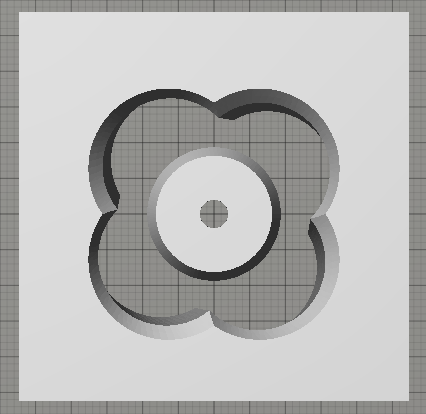

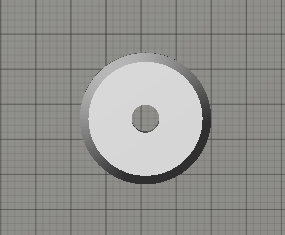

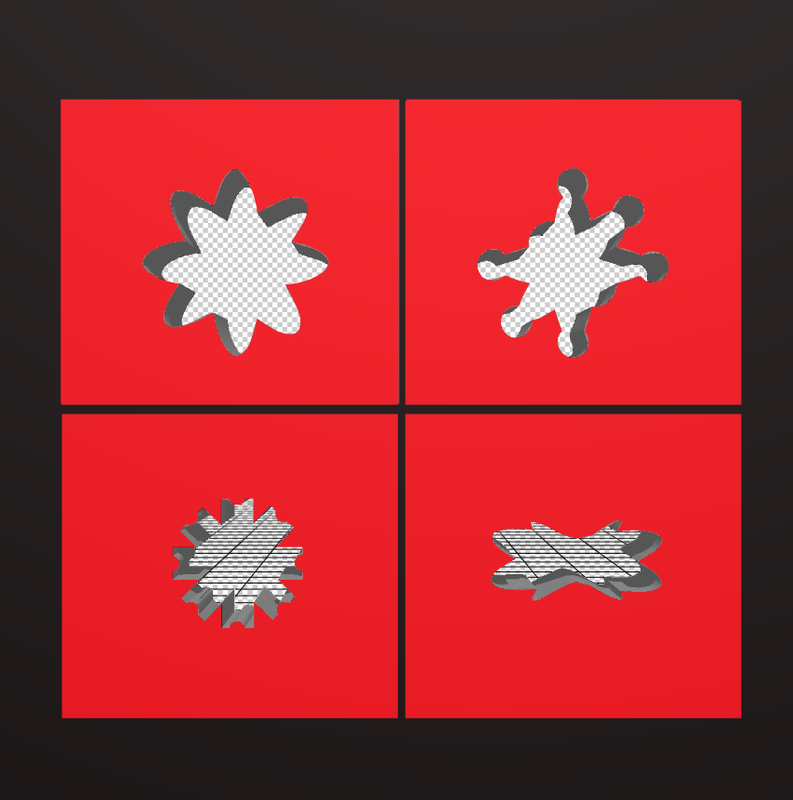

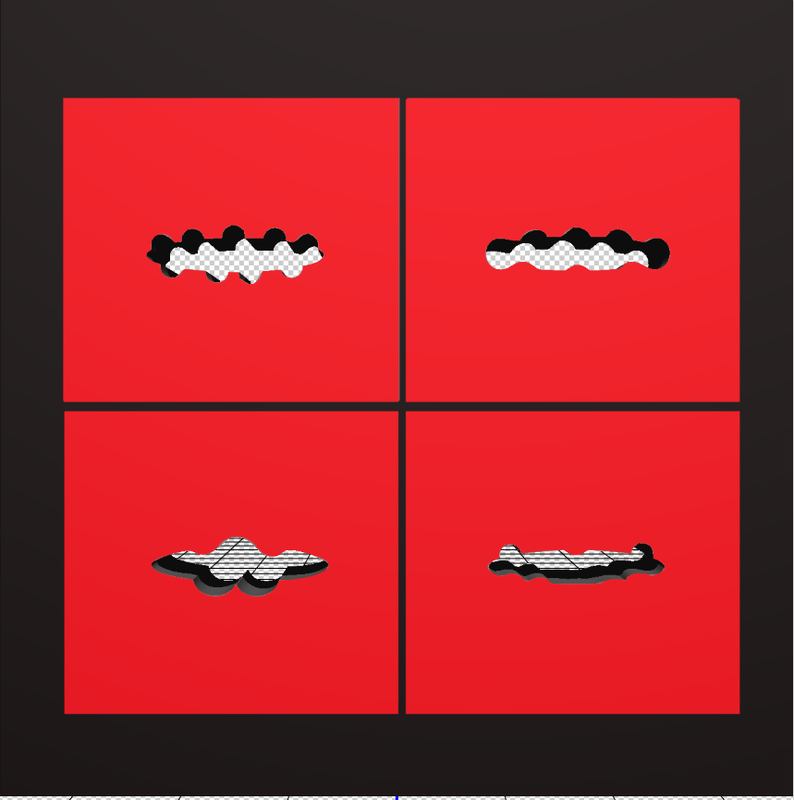

Extruder Dies.

Our extruder dies are made with the use of a North Star Extruder in mind. The print parameter for our dies fit and work well with a 108mm x 108mm x 6mm print at 45% infill. We are producing dies in our studio with a standard Makerbot printer using PLA filament. All dies printed at this density infill are being used in combination with a printed blockout plate at 100% infill at 3-5mm thickness. The 100% infill rigid block out plate allows for lesser density infill dies and quicker production speed. While 100% infill dies are stronger we've found that density level to be un-necessary and time consuming. The stacked die and block out plates are more than sufficient in the extruder using a medium stiffness clay bodies. Side Profile Handle dies on the other hand require a significantly denser infill do to the largely unsupported undercut areas of the handles. Experiment and see what works best for you.

|

|

|

|

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||