Clay Dust and Glaze Materials

Equipment (wheels, slab rollers, kilns)

Fired Materials and the Makers Responsibility

Environmental Issues

- Moisture to combat. Wet clean up with moist sponges and mops.

- Clean up when work session is over. (wheel and hand building)

- Moist towels and not personal clothing for wiping hands.

- If it spills, clean it immediately (foot traffic spreads dust around and into the air as well as grinds coarse materials into fine dust particles.

- Controlling exposure to toxins. (heavy metals, silica, and other toxins [barium])

- Water/sponge clean up of all glaze materials.

- Dust masks (respirators must be worn when mixing glaze or clay and when spraying)

Equipment (wheels, slab rollers, kilns)

- Studio equipment must bee used with caution.

- Water is a hazard when using electrical tools.

- Students should be taught the safe use of each piece of equipment before they are allowed to use on their own.

- Students must wear protective eye wear and be dressed appropriately to operate any equipment that could produce flying particles (spray both, glaze mixer). This is only after a safety demo individually and the instructor feel the student can handle the equipment.

- Kilns. Students do not have access to kilns unless they meet guidelines set by instructor:

- Students must have gone through safety lecture on kiln use.

- Students must be supervised when loading or unloading work, especially if it is the work of other students.

- Students must have a faculty member present if they fire a kiln. (during programming or directly firing of gas kilns)

- Students must display an above average aptitude for handling equipment. This rarely if ever happens in the first semester of ceramics courses.

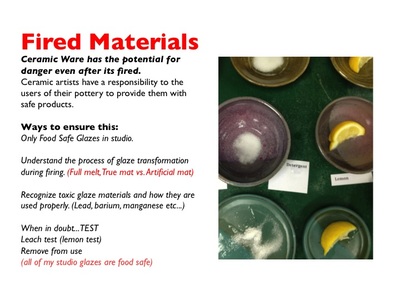

Fired Materials and the Makers Responsibility

- As a maker of Utilitarian objects, Ceramic artists have a responsibility to ensure the safety of their products and remove potential risks to the users of their wares.

- Fired glazes can still present a health risk to user. To prevent this we do not use non food safe glazes or glazes that have a potential to leach materials.

- Glazes must be food safe for use on utilitarian objects. As a rule there is only food safe glazes available in the general glaze line up.

- Mat Glazes should be true mats, micro crystalline mats that are full melt glazes to ovoid leaching.

- Questionable glazes should be leach tested (lemon test) or removed form the general glaze line up.

- As a rule of thumb I prefer all studio glazes to be safe for use in all applications. No special use glazes or sculpture only glazes are openly available. At this level of academic exposure, it is too soon to introduce variables that can be confusing, especially when confusion can lead to health and safety risks.

Environmental Issues

- Glaze materials should not be rinsed down the drains. Collection bins for waste glaze should be used and waste disposed of properly. This will prevent toxins from entering our drains. It is our job to safely dispose of and manage the materials we use as ceramic artists and students.

- No toxic materials go down the drain. (we use recycling methods to deal with remnant glazes and material). Recycling glazes are used and have been used successfully to deal with remnants and contaminated glazes. NO GLAZE GOES IN THE TRASH OR DOWN THE DRAIN.

- Glaze should not be disposed of in proper waste cans provided by facility management.

- Clay can be re used and recycled if unfired. We also recycle to provide students with lower cost alternatives to book store clay. It also acts as a fundraising method for our Ceramics Club at Reedley College as well as an educational opportunity to understand the process of clay making, recycling and general clay knowledge.